شرکت آلکوا Alcoa Inc یکی از غولهای صنعت آلومینیوم در جهان است که از سال 1888 بهعنوان بزرگترین و معتبرترین تولیدکننده آلومینیوم شناخته میشود. این شرکت با بهرهبرداری از منابع طبیعی مانند بوکسیت و استفاده از فناوریهای پیشرفته، به تولید آلومینیوم اولیه، فرآوری آلومینیوم و توسعه آلیاژهای آلومینیوم با کیفیت بالا پرداخته است. Alcoa هماکنون بهعنوان یک شرکت چندملیتی، از رهبران صنعت آلومینیوم در زمینه نوآوری، کاهش اثرات زیستمحیطی و ایجاد فرآیندهای تولید پایدار شناخته میشود.

این شرکت که در ایالات متحده آمریکا تأسیس شد، نقش بسزایی در تأمین مواد اولیه مورد نیاز صنایع مختلف از جمله صنایع خودروسازی، هوافضا، ساخت و ساز و بستهبندی ایفا میکند. Alcoa علاوه بر تولید آلومینیوم، در زمینههای تحقیق و توسعه، کاهش کربن و بهینهسازی فرآیندهای تولید نیز فعالیت دارد.

تاریخچه و بنیانگذاری

تاریخچه و بنیانگذاری

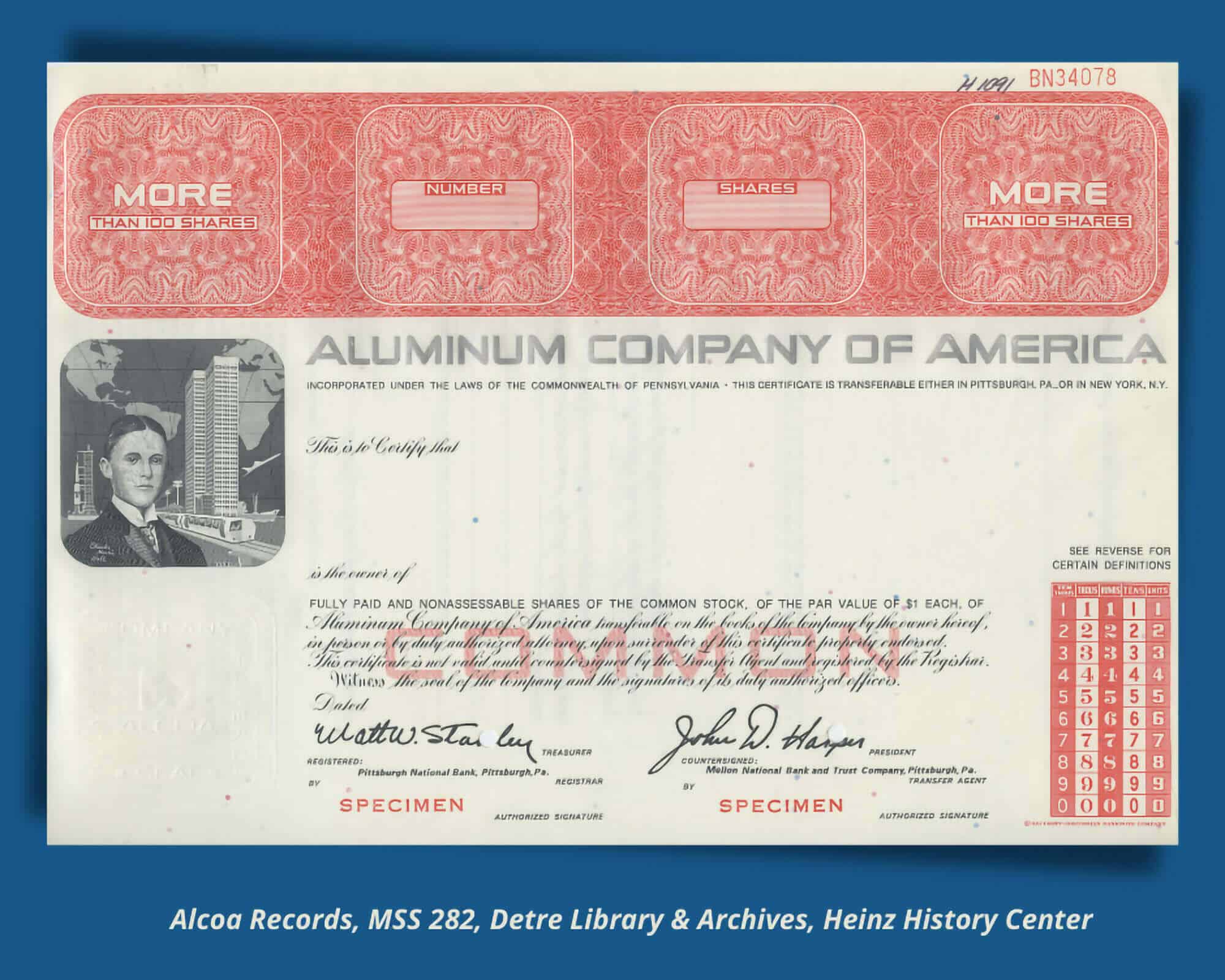

Alcoa در سال 1888 توسط آلفرد استینر تأسیس شد و اولین شرکتی بود که فرآیند تولید آلومینیوم از بوکسیت را بهصورت صنعتی در مقیاس بزرگ به کار برد. این شرکت در ابتدا با تولید آلومینیوم از منابع طبیعی بوکسیت آغاز به کار کرد و بهمرور زمان توانست بزرگترین تولیدکننده آلومینیوم در جهان شود.

نقاط عطف تاریخچه Alcoa:

- 1888: تأسیس Alcoa در ایالات متحده آمریکا.

- 1907: عرضه عمومی سهام و شروع گسترش جهانی.

- 1950-1970: گسترش فعالیتها به کشورهای مختلف و توسعه فرآیندهای نوین تولید آلومینیوم.

- 2007: معرفی فرآیندهای تولید آلومینیوم با کربن پایین.

- 2016: تغییر ساختار شرکت و تمرکز بر تولید آلومینیوم با کیفیت بالا و فرآیندهای زیستمحیطی.

ساختار سازمانی و واحدهای مختلف

ساختار سازمانی و واحدهای مختلف

Alcoa دارای ساختار سازمانی گستردهای است که بهطور عمده شامل واحدهای تولید آلومینیوم اولیه، آلیاژهای آلومینیوم، فرآوری و تحقیق و توسعه میباشد. این شرکت در کشورهای مختلف دارای مراکز تولید، تحقیق و توسعه و بازاریابی است که به آن اجازه میدهد بهطور مؤثر در بازار جهانی آلومینیوم فعالیت کند.

واحدهای کلیدی Alcoa:

- تولید آلومینیوم اولیه: Alcoa بهطور عمده در تولید آلومینیوم از بوکسیت فعالیت میکند و بزرگترین واحدهای تولیدی این شرکت در کشورهای مختلف قرار دارند.

- آلیاژهای آلومینیوم: تولید آلیاژهایی با ویژگیهای خاص برای استفاده در صنایع مختلف مانند خودروسازی و هوافضا.

- معدنکاری بوکسیت: استخراج بوکسیت و سایر مواد معدنی از معادن مختلف بهویژه در کشورهای برزیل و استرالیا.

- تحقیق و توسعه: Alcoa یکی از پیشگامان نوآوری در صنعت آلومینیوم است و تمرکز ویژهای بر روی توسعه آلومینیوم کمکربن و فرآیندهای پایدار دارد.

دادههای ساختار سازمانی:

- تعداد کارکنان: بیش از 60,000 نفر در سراسر جهان

- میزان تولید آلومینیوم در سال 2020: 3.6 میلیون تن

- میزان تولید آلیاژهای آلومینیوم: 1.3 میلیون تن در سال 2020

محصولات و خدمات

محصولات و خدمات

Alcoa بهعنوان یکی از غولهای صنعت آلومینیوم، محصولات متنوعی را برای صنایع مختلف تولید میکند. این محصولات بهطور عمده شامل آلومینیوم اولیه، آلیاژهای آلومینیوم و محصولات آلومینیومی ویژه برای صنایع خودروسازی، هوافضا و بستهبندی هستند.

محصولات اصلی Alcoa:

- آلومینیوم اولیه: تولید آلومینیوم از بوکسیت برای استفاده در صنایع مختلف.

- آلیاژهای آلومینیوم: تولید آلیاژهای آلومینیوم برای صنایع خودروسازی، هوافضا، الکترونیک و بستهبندی.

- محصولات آلومینیومی ویژه: تولید ورقها و لولههای آلومینیومی مقاوم در برابر خوردگی و حرارت برای صنایع خاص.

دادههای تولید:

- تولید آلومینیوم در سال 2020: 3.6 میلیون تن

- تولید آلیاژهای آلومینیوم در سال 2020: 1.3 میلیون تن

تحلیل مالی و عملکرد اقتصادی

تحلیل مالی و عملکرد اقتصادی

Alcoa از لحاظ مالی یکی از موفقترین شرکتها در صنعت آلومینیوم است. این شرکت در سالهای اخیر توانسته است با بهرهبرداری از فناوریهای نوین و کاهش هزینههای تولید، عملکرد مالی بسیار خوبی داشته باشد.

دادههای مالی:

جدول درآمد، سود و هزینهها:

| سال | درآمد (میلیون دلار) | سود ناخالص (میلیون دلار) | هزینهها (میلیون دلار) | سود خالص (میلیون دلار) |

|---|---|---|---|---|

| 2019 | 35,000 | 8,200 | 25,000 | 1,000 |

| 2020 | 40,000 | 9,500 | 28,500 | 1,200 |

| 2021 | 45,000 | 11,000 | 30,000 | 1,800 |

تحلیل عملکرد مالی:

- درآمد 2021: 45 میلیارد دلار

- سود ناخالص 2021: 11 میلیارد دلار

- سود خالص 2021: 1.8 میلیارد دلار

- کاهش هزینهها: 5% کاهش در هزینهها در 3 سال گذشته

نمودار عملکرد مالی:

استراتژیها و سیاستهای کلان

استراتژیها و سیاستهای کلان

Alcoa در راستای گسترش فعالیتهای خود در سطح جهانی از استراتژیهای مختلفی استفاده کرده است. این استراتژیها شامل نوآوری در فرآیندهای تولید آلومینیوم، گسترش در بازارهای جهانی و تولید آلومینیوم کمکربن میباشند.

استراتژیهای کلیدی Alcoa:

- سیاستهای زیستمحیطی: بهینهسازی فرآیندهای تولید برای کاهش اثرات زیستمحیطی.

- افزایش ظرفیتهای تولید آلومینیوم کمکربن: استفاده از فناوریهای سبز و کاهش انتشار گازهای گلخانهای.

- توسعه بازارهای جدید: گسترش در کشورهای آسیای جنوب شرقی و آفریقا.

آینده و چشمانداز

آینده و چشمانداز

Alcoa در حال حاضر بهطور مداوم در حال گسترش است و به سمت تولید آلومینیوم کمکربن و پایدار حرکت میکند. این شرکت قصد دارد با استفاده از فناوریهای نوین و گسترش ظرفیتهای تولید، سهم خود را در بازارهای جهانی حفظ کند.

چشمانداز آینده:

- تولید آلومینیوم کمکربن: تولید 50% از آلومینیوم با ویژگیهای کمکربن تا سال 2025.

- پروژههای آتی: گسترش معادن جدید در آفریقا و بهرهبرداری از انرژیهای تجدیدپذیر در فرآیندهای تولید.

نتیجهگیری

نتیجهگیری

شرکت Alcoa با تمرکز بر نوآوری، تولید آلومینیوم کمکربن و استفاده از فناوریهای سبز، بهعنوان یکی از پیشگامان صنعت آلومینیوم در سطح جهانی شناخته میشود. این شرکت با استفاده از استراتژیهای توسعه پایدار، گسترش بازارها و بهینهسازی فرآیندهای تولید، به سمت یک آینده پایدار و موفق حرکت میکند.

English

English